Solutions during the cultivation phase

The life of your potted plant in the greenhouse (or in the open field) starts with sticking the cutting or seedling in a pot. What happens next? Are they moved to a cultivation floor by hand or by a forklift truck, or are they grown on tables or in containers? Which aspects of the growing process do you want to automate, and to what extent? WPS has the right customer-specific solution for you, from the smarter utilization of your cultivation space to plant conveyors or fully automated gutter-based cultivation systems.

SmartFlo conveyors

The SmartFlo system allows plants to be easily transported within different zones or from one zone to another.

Walking Plant System

The plants in this fully automated cultivation system are grown in gutters.

Robotics

The robotic arm automatically picks up the potted plants and sets them down again in a container or conveyor belt. It can handle multiple tasks.

.png)

Workstations

WPS workstations ensure that employees work ergonomically and efficiently and, as a result, derive more pleasure from their work.

Data Registration

Want to know everything about your plant? RFID tags, barcodes and QR codes all help you keep track of your plants from the moment they are potted.

Irrigation

WPS provides various systems for watering and irrigation to ensure that your potted plants automatically receive the right amount of water.

Plant Growth Cell (PGC)

This patented hexagonal growing vase saves space and ensures that your plants are grown under the best possible conditions.

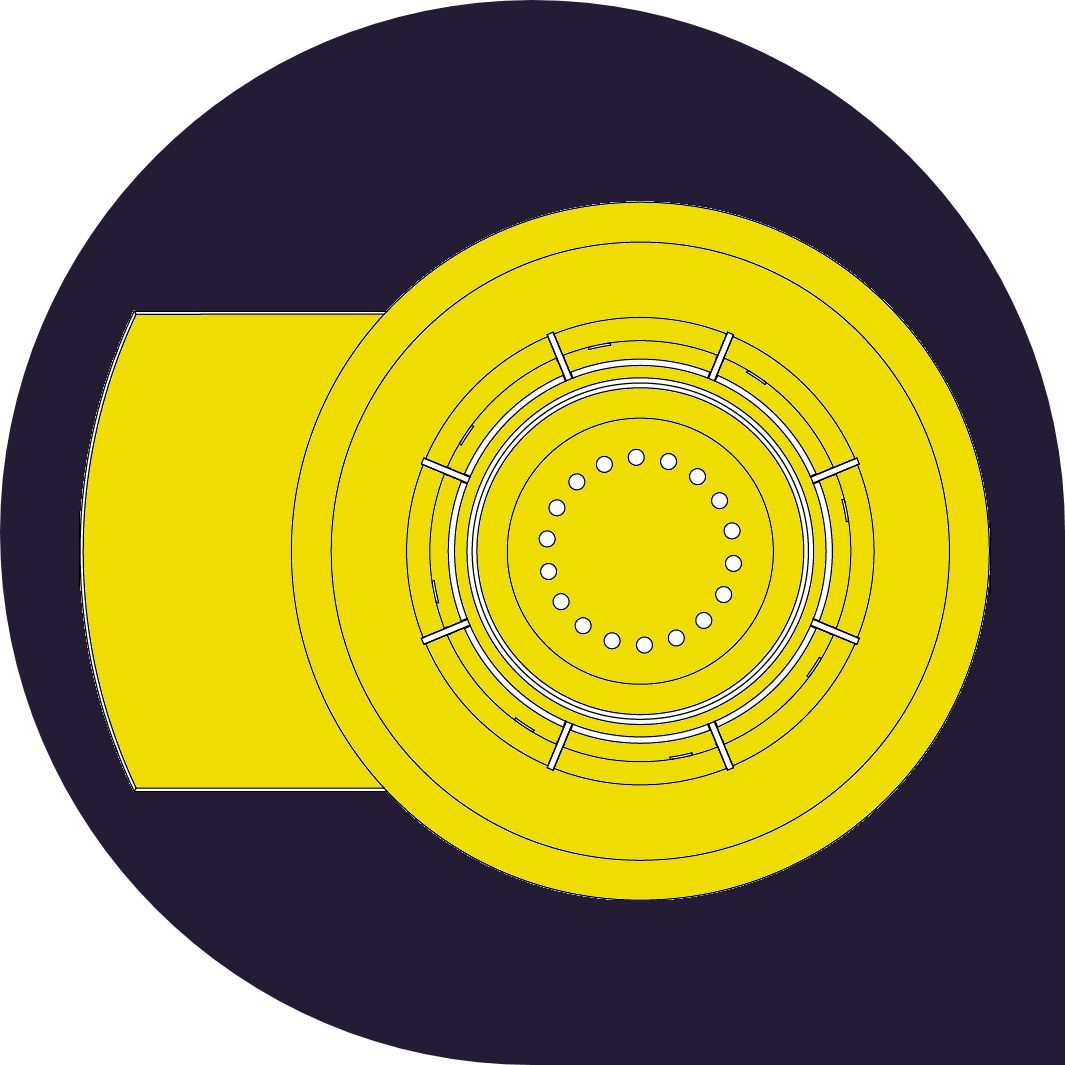

Oval Plant Carrier (OPC)

This carrier ensures the stable transport of potted plants on a conveyor belt, optionally linked to a track & trace system.